Small, Complex, & Large PCB Assemblies

Vital Systems | PCB Assembly | Reno Nevada

Vital Systems offers 39 years of printed circuit board (PCB) assembly experience. Over these years our fine-tuned processes allow us to deliver high quality functioning boards, out of every 100 “untested” PCB assemblies, 99 will pass electrical testing, right out of the shipping box. The remaining 1% fail due to a combination of bad components or assembly issues. We specialize in small, complex, and large PCB Assemblies.

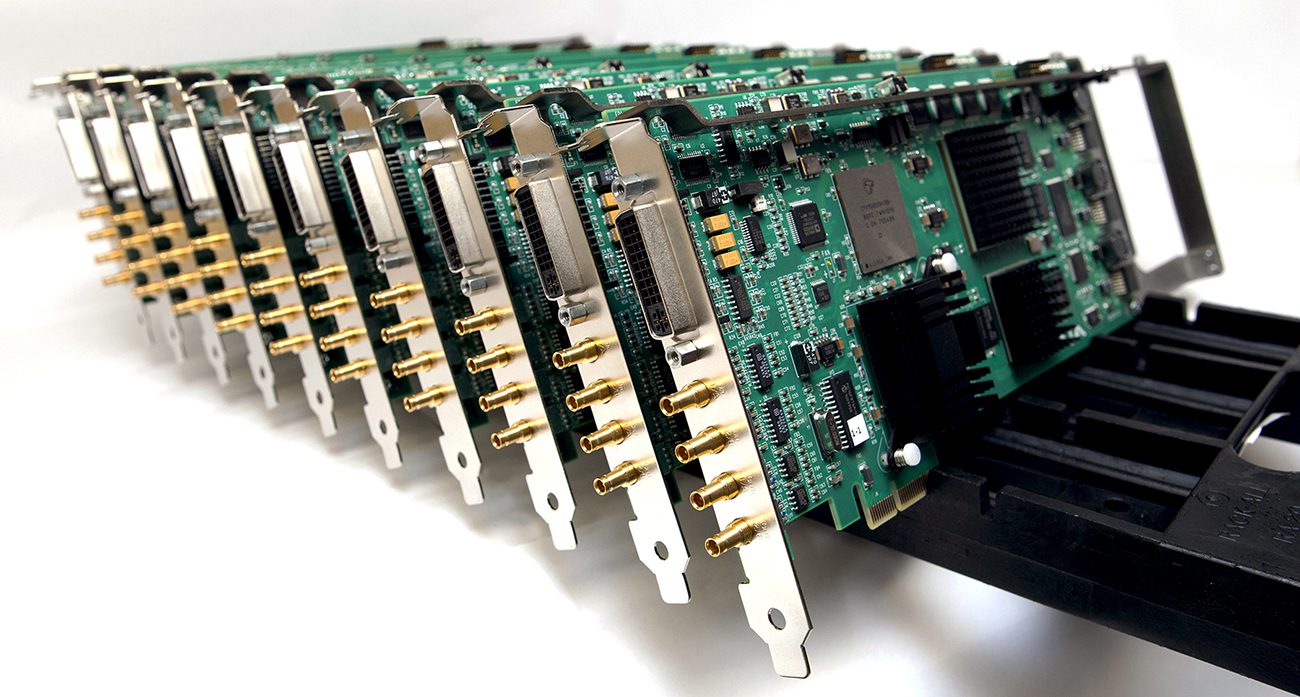

Large PCB Assemblies

Vital Systems has the depth of experience in assembling large, small and complex PCB assemblies for military and commercial applications. As required, we develop special equipment to complete the projects like this PCBA measuring 3 feet by 4 feet.

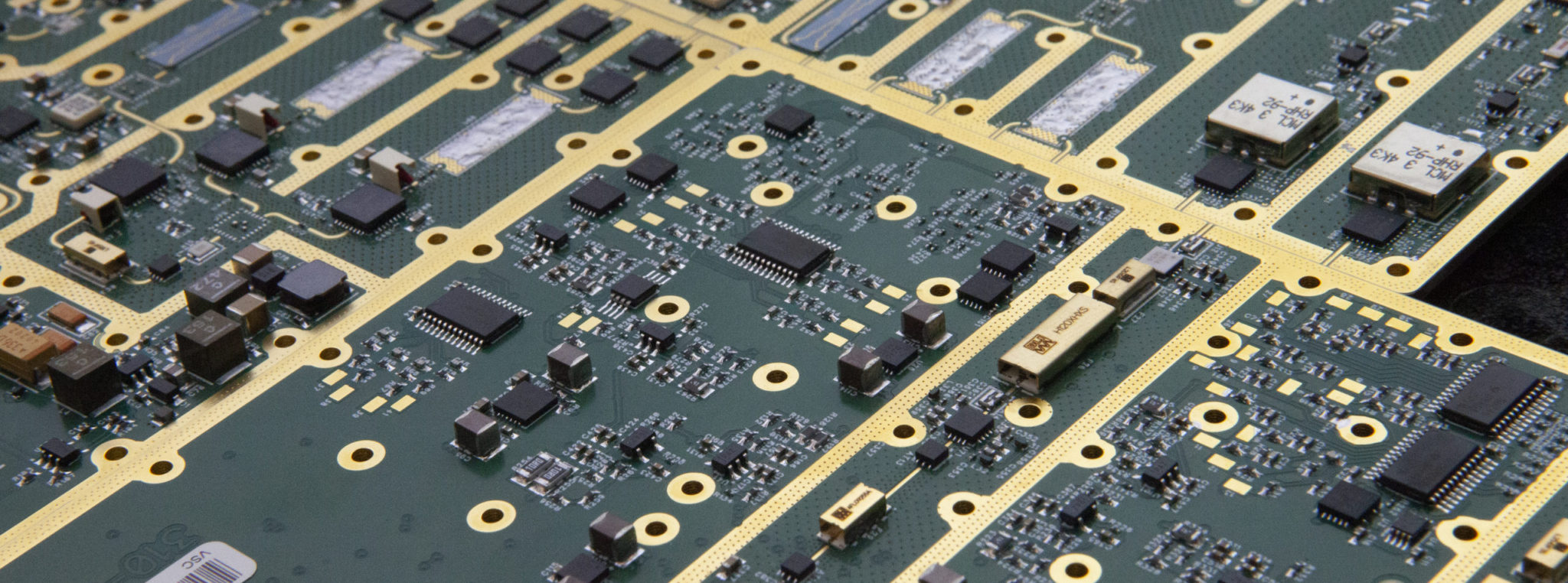

Complex PCB Assemblies

Our specialty lies in assembling densely populated PCB assemblies, for high frequency and digital applications. Combinations of such technologies are typically used in military and video processing equipment.

RF filters, BGA and QFN devices assembled to meet IPC-A-610 Class 3. A strict standard for spacecraft bearing electronics or for highly reliable military applications.

NASA Quality

NASA, Military and Aerospace companies require the highest quality in electronic assemblies. In 1986 US Navy certified Vital Systems to assemble weapons grade electronic for military and space applications. This certification helped Vital Systems win many defense contracts. Today, we continue to set quality standards, that our loyal customers have enjoyed for decades. IPC-A-610 Class 3

Camera & IOT

Vital Systems assembles small PCBA, as small as 0.25 inch square (6mm x 6 mm) for use in cameras and various IOT devices. We build these by the thousands. Each of these small PCB assembly is programmed and tested before shipping to the customers.

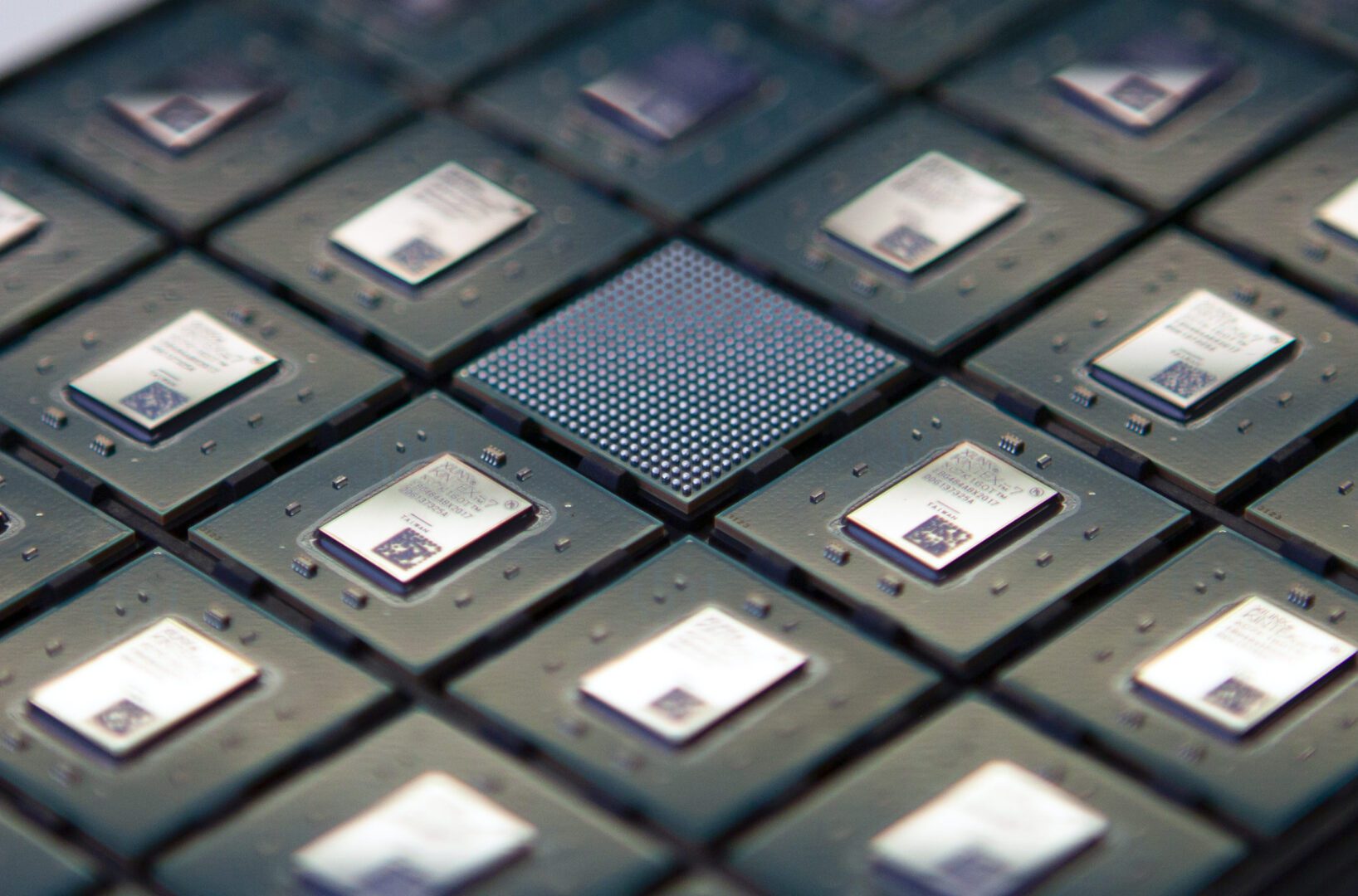

BGA, QFN, & Small Components

BGA & QFN

Miniaturization and large-scale integration has moved electronic industry to pack more power and capabilities in Ball Grid Array BGA, Quad Flat No-Lead QFN devices. We specialize in populating these devices, with less than 30 defects per million.

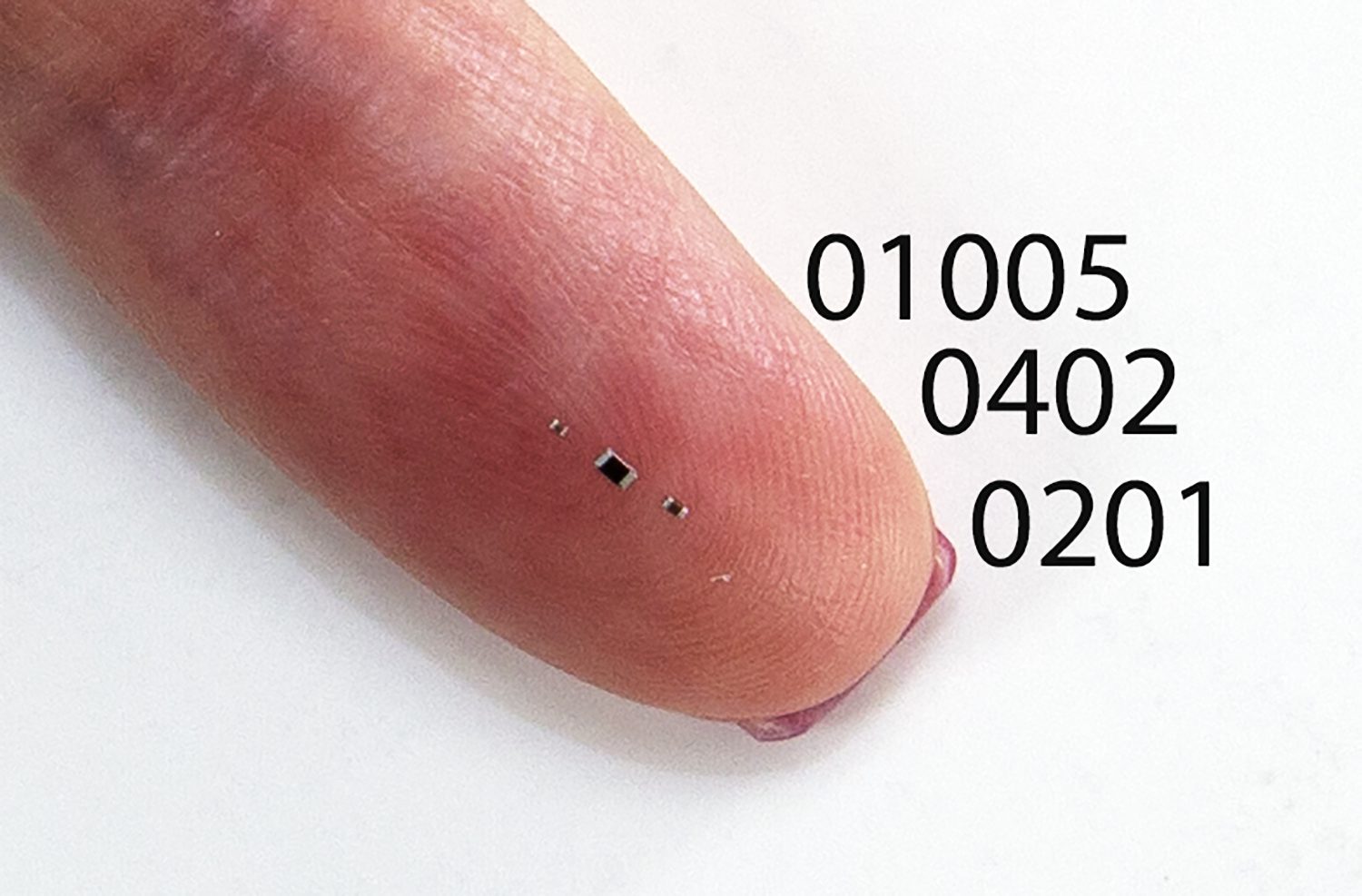

Small Components

With the precision of today’s process equipment, we can reliably install exceedingly small surface mount components like 0201 inch (0603 mm), and smaller yet down to 01005 inch (0402 mm).

Inspection Systems

X-Ray Inspection

X-Ray technology employed at Vital Systems is capable of rendering images that are impossible for human inspectors to see. That is the integrity of every soldered connection. Heat sinking for QFN is crucial and this technology accurately provides this important information.

Optical Inspection

Automated Optical Inspection or AOI is the latest technology in the industry for visual inspection . This 3D inspection system is extremely fast and accurate. That is how we inspect millions of soldered connections and that is how we deliver the highest quality.

Soldering

Electronic Testing

Programming & Testing

Once complete the PCB assemblies are powered for the first time, here they receive their firmware. Some PCBA will be tested to assure all components in various circuits are functioning normally.

In Circuit Testing

Vital Systems offers biased or unbiased In Circuit Testing ICT. When required, this test verifies given circuit function normally.

Full Function Testing

After the PCBA are fully assembled, these units are submitted to a final Full Function Test. This test simulates, how these units will perform in the field when deployed.

Flying Probe Testing

Customers require each passive and active components to be checked for proper device type, value, orientation and solder connection integrity.